Our Services

On site and in-house load testing carried out on a wide range of lifting equipment, access equipment and height safety equipment.Upon successful load test completion, all tested equipment is marked accordingly, registered and test certificates are issued thereafter.

On site and in-house load testing carried out on a wide range of lifting equipment, access equipment and height safety equipment.Upon successful load test completion, all tested equipment is marked accordingly, registered and test certificates are issued thereafter. Experienced personnel within the lifting industry offering repair services on site or in-house.

Experienced personnel within the lifting industry offering repair services on site or in-house.

Quarterly and bi-annual maintenance programmes with detailed service sheets issued to customer before site departure.

All required repairs are followed up by our service engineers.

On site and in-house statutory inspections carried out as per The Safety, Health and Welfare at Work (General Application) Regulations, 2007 with detailed GA1 & GA3 inspection certificates issued upon completion.

On site and in-house statutory inspections carried out as per The Safety, Health and Welfare at Work (General Application) Regulations, 2007 with detailed GA1 & GA3 inspection certificates issued upon completion.

We offer a unique colour code tagging system to give all equipment users a clear indication of the current status of the equipment.

We mount colour code charts at our customers works to give all equipment users a visual indication of the current colour code in play.

Since the 1st July 2014, it is a legal requirement for all fabricated structural steelworks delivered to site to be CE Marked. Designers and specifiers need to amend their specifications to include references to the new standards.

Since the 1st July 2014, it is a legal requirement for all fabricated structural steelworks delivered to site to be CE Marked. Designers and specifiers need to amend their specifications to include references to the new standards.

Through our fabrication and design sector, we are pleased to inform all our customers that we have achieved certification through our business partners, EN 1090-1:2009 +A1:2011 – Execution class 2

This certification allows us to issue the CE mark with all of Crane Check Lifting Services required manufactured products under the scope of EN 1090-1.

CCLS through our business partners also have a certified factory production control system, this allows full traceability on all our products both purchased and produced to ensure all our customers receive a high standard quality products.

We have certified welding procedures in place for butt and fillet welds up to and including S355 materials.

We also have procedures in place for pipe to plate weld, tack weld and weld repairs.

Load Testing Service

On site and in-house load testing carried out on a wide range of lifting equipment, access equipment and height safety equipment.

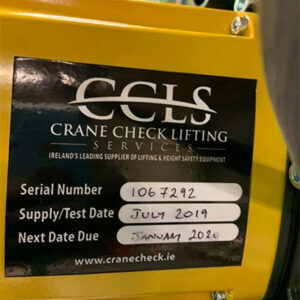

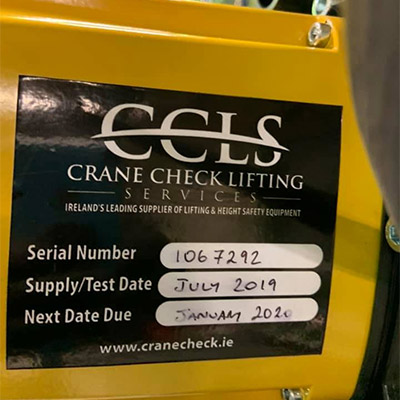

Upon successful load test completion, all tested equipment is marked accordingly, registered and test certificates are issued thereafter.

Repair and Periodic Service

Experienced personnel within the lifting industry offering repair services on site or in-house.

Quarterly and bi-annual maintenance programmes with detailed service sheets issued to customer before site departure.

All required repairs are followed up by our service engineers.

Statutory Inspections, Periodic Service & Breakdown Service

On site and in-house statutory inspections carried out as per The Safety, Health and Welfare at Work (General Application) Regulations, 2007 with detailed GA1 & GA3 inspection certificates issued upon completion.

We offer a unique colour code tagging system to give all equipment users a clear indication of the current status of the equipment.

We mount colour code charts at our customers works to give all equipment users a visual indication of the current colour code in play.

Fabrication Service

Since the 1st July 2014, it is a legal requirement for all fabricated structural steelworks delivered to site to be CE Marked. Designers and specifiers need to amend their specifications to include references to the new standards.

Through our fabrication and design sector, we are pleased to inform all our customers that we have achieved certification through our business partners, EN 1090-1:2009 +A1:2011 – Execution class 2

This certification allows us to issue the CE mark with all of Crane Check Lifting Services required manufactured products under the scope of EN 1090-1.

CCLS through our business partners also have a certified factory production control system, this allows full traceability on all our products both purchased and produced to ensure all our customers receive a high standard quality products.

We have certified welding procedures in place for butt and fillet welds up to and including S355 materials.

We also have procedures in place for pipe to plate weld, tack weld and weld repairs.